Description

Pyrotechnic rear headrest for PEUGEOT 307 CC cars

Part description

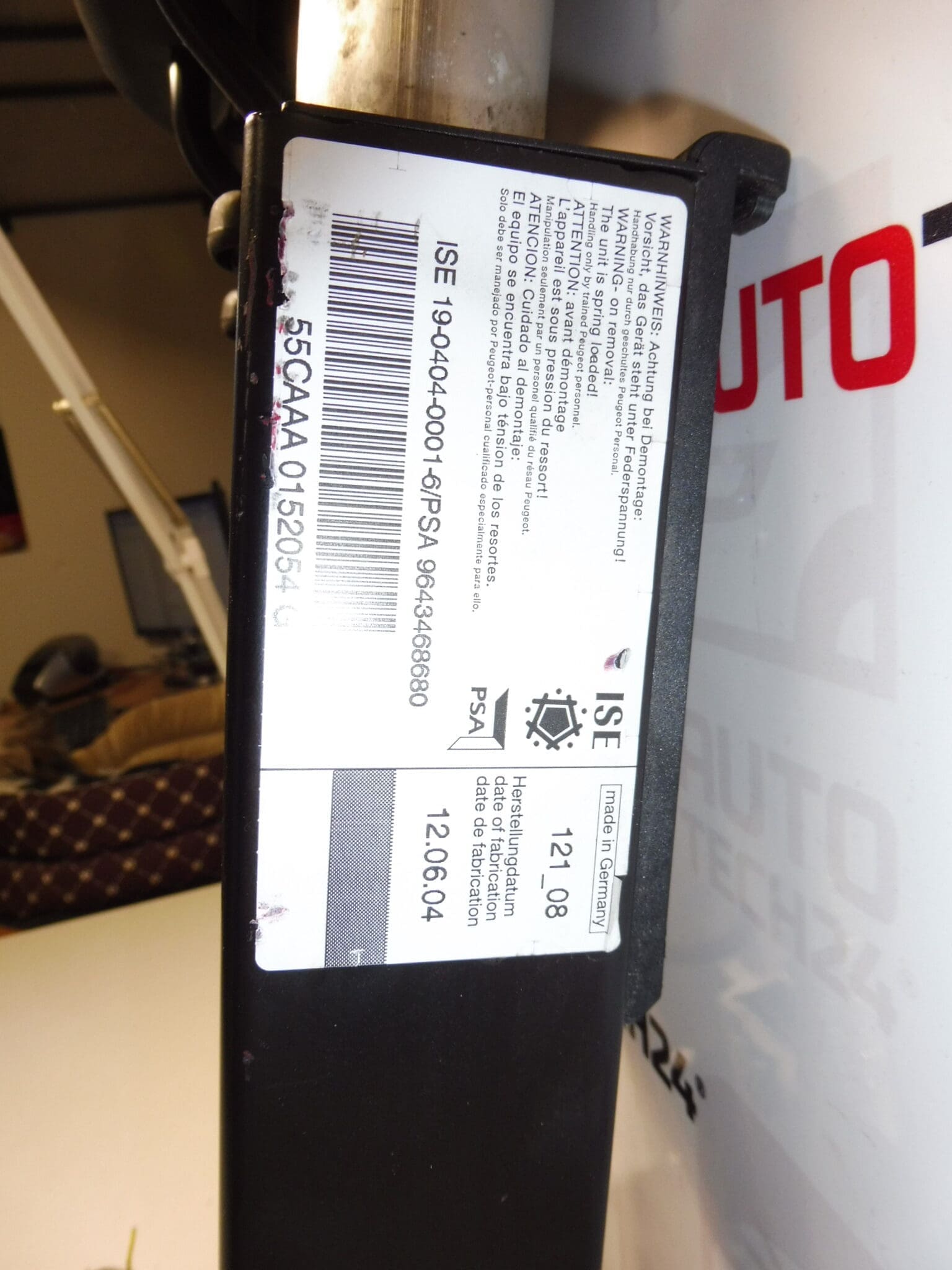

This used part is intended for the Peugeot 307 CC passive safety system and is a pyrotechnic rear headrest (safety arch). In practice, it is a component that is designed to fulfill its protective function in the event of activation of the security system. Thanks to the indicated designation, the part is often searched directly by product number.

When choosing, focus on matching the marking and design with the existing piece in the car – correct identification is essential for pyrotechnic elements.

Technical information

- Manufacturer: Stellantis (Citroën/Peugeot)

- Model: Peugeot 307 CC

- Other numbers: 885290 NFP

Product codes

- Product codes: 9643468680, 885290

Installation recommendations

Generally/typically extreme care must be taken with pyrotechnic safety features, and the exact steps may vary depending on the specific design of the car. If you are unsure of the procedure, refer to the service procedure for that model.

1) Before assembly

- Check that the part corresponds to the ordered version and that the codes 9643468680 / 885290 (or other markings on the part) match.

- Compare the shape, fit and connectors with the old part (same mechanical fit, same types of connectors).

- Visually check whether the part is not damaged (cracks, deformation, damaged connectors, traces of intervention/activation).

2) Necessary tools and materials

- Normal set of hand tools (ratchet/bit, screwdrivers as needed)

- Plastic crowbar for removing upholstery/covers (typical)

- Protective gloves and goggles

- Contact cleaner (optional, depending on the condition of the connectors)

3) Step-by-step assembly procedure

- Turn off the ignition, remove the key/disconnect the access medium and secure the car against unwanted movement.

- Disconnect the battery and wait a reasonable time for the passive safety system to deactivate (according to the manufacturer’s service instructions).

- Get access to the part by removing the necessary covers/upholstery (typically plastic parts and fillers around the mounting location).

- Before disconnecting, note the wiring route and the position of the connectors (or take a photo for reassembly).

- Disconnect the electrical connectors carefully – do not pull on the cables, always release by the body of the connector.

- Dismantle the fasteners and remove the original part so as not to damage the surrounding parts and wiring.

- Compare the old and new part “side by side” one more time (fittings, connectors, cable lengths).

- Install the part in its original place and seat it without tension (the wiring must not be stretched or pinched).

- Secure fixing back to all mounting points.

- Connect the connectors and check that they click and lock properly.

- Reinstall all the removed covers/upholstery and check that there are no scratches or loose parts.

- Connect the battery and perform a function check according to the car’s capabilities (including checking the lights on the dashboard).

-

4) Post-assembly checks and test drive/function verification

- Check that the connectors are secure, the cabling is routed correctly and is not rubbing anywhere.

- After turning on the ignition, observe for any warning messages/lights related to the security system.

- Do a short test drive and re-verify that there are no warnings and that nothing is throwing/interfering.

5) The most common assembly mistakes + how to avoid them

- Not disconnecting the battery before handling: always disconnect and follow the manufacturer’s safety procedure.

- Damage to connectors/cabling during disassembly: disconnect connectors correctly, do not pry with force.

- Bad cabling (pinching, chafing): checking of grommets and cable routes before final assembly.

- Part mismatch (different design/fitting): always compare the codes and physical design with the old part before assembly.

Reasons why the part is damaged

- Activation of the pyrotechnic mechanism in the event of an accident or security event.

- Mechanical damage (deformation, broken attachment) due to impact or unprofessional disassembly.

- Damage to connectors and cabling (tear out, broken securing, oxidation of contacts).

- Intrusion of moisture into electrical connections and subsequent problems with contacts.

- Improper handling of components of the passive safety system (falling of a part, rough handling, storage in unsuitable conditions).