Description

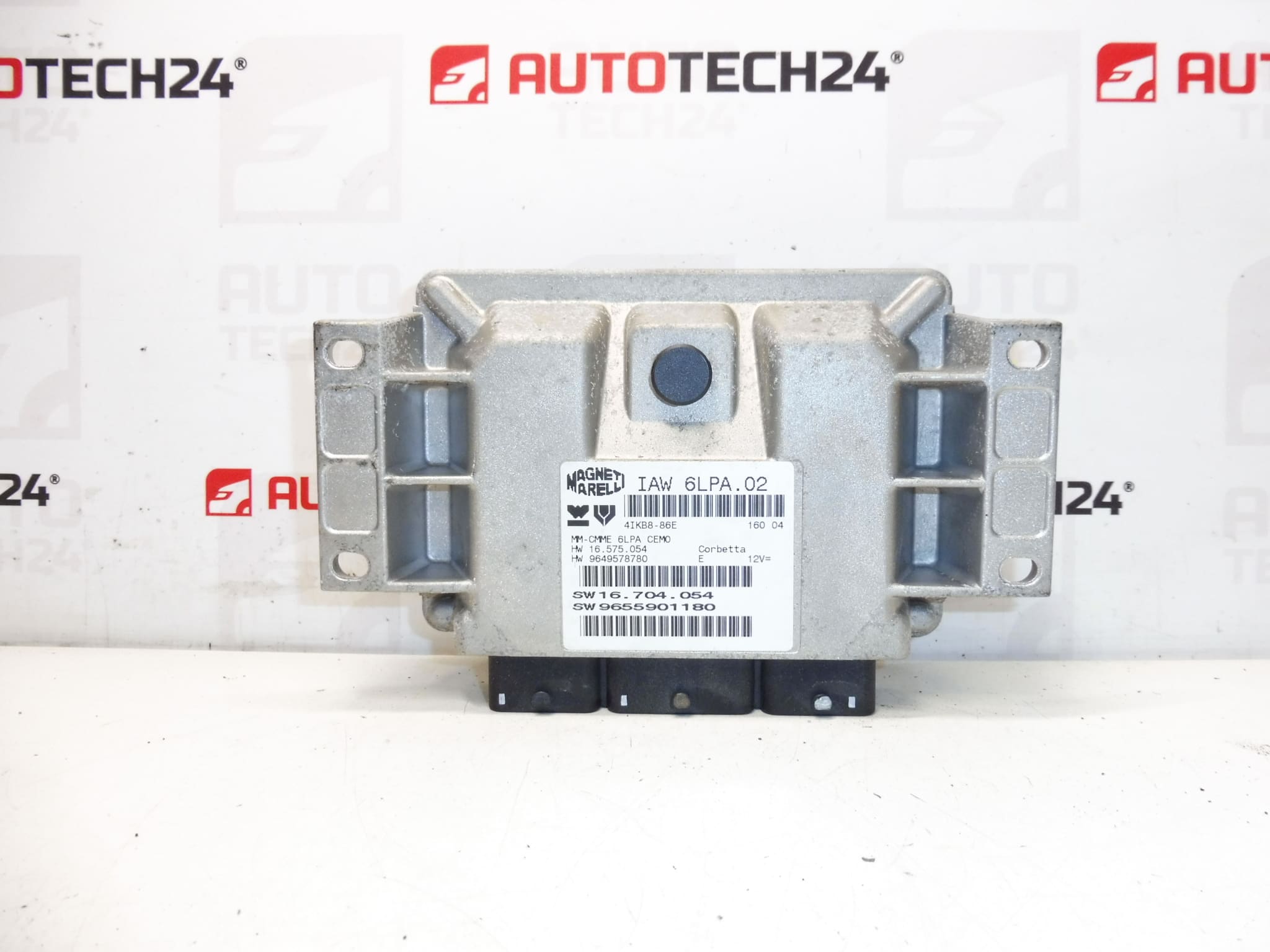

Control unit MAGNETI MARELLI IAW IAW 6LPA.02 for engine 2.0i 16V 130 KW RFK

It is from a PEUGEOT 307 CC 2004

Part description

Used Injection Control Unit Magneti Marelli (IAW) designed for Citroën/Peugeot (Stellantis/PSA) cars. This particular piece is marked IAW 6LPA.02 and comes from a Peugeot 307 CC (2004). In practice, these units are solved in the event of engine control malfunctions, when it is necessary to maintain the correct product number and matching markings on the label.

If you’re looking for a part primarily by number, stick to 9655901180 and 9649578780 (see below) – that’s the fastest way to get the correct replacement.

Technical information

- Manufacturer: MAGNETI MARELLI

- Model: PEUGEOT 307 CC (2004)

- Other numbers: IAW 6LPA.02, 1942C8, 1942C9, NFP

Product codes

- Product codes: 6LPA.02, 9655901180, 9649578780, 1942C8, 1942C9

Installation recommendations

Generally/typically for injection control units, the exchange itself is only part of the work – correct commissioning (data/coding) is also important. The exact procedure may vary depending on the specific car design and equipment.

1) Before assembly

- Carefully compare the markings on the unit: IAW 6LPA.02, the numbers 9655901180 and 9649578780 and possibly other codes (1942C8/1942C9).

- Check the connectors (no bent pins, no signs of corrosion/oxidation), the condition of the cover and any signs of moisture.

- If you are replacing a unit due to a wiring fault, first find out the cause (eg damaged harness, leak), otherwise the problem may return.

2) Necessary tools and materials

- Basic set of hand tools (ratchet/extension, screwdrivers according to design)

- Tools for gentle work with connectors (small flat tool for connector fuses)

- Electrical contact cleaner (optional), dry cloths

- Diagnosis for subsequent steps (as needed and possible)

3) Step-by-step assembly procedure

- Turn off the ignition, wait a short time for the systems to sleep.

- Disconnect the battery (to prevent damage to the unit and connectors during handling).

- Get access to the unit (according to the specific version of the car).

- Unlock the connectors and disconnect the connectors by pulling on the connector body (not the cables).

- Unmount the unit and remove it.

- Compare the old and new piece (numbers, type of connectors, mechanical attachment).

- Install the unit back into the bracket/mount, seat it without tension.

- Connect the connectors – they must be fully seated and the fuses must be clearly secured.

- Check that the wiring is not pinched and that there is no risk of rubbing against sharp edges.

- Connect the battery.

- Commission the unit (see below) and then verify start/function.

-

4) Post-assembly checks and test drive/function verification

- Verify that the connectors are secure and nothing is loose.

- Perform a diagnostic check and verify the communication of the unit (according to service options).

- After successful commissioning, verify stable engine operation and basic functions during a short test drive.

5) The most common assembly mistakes + how to avoid them

- Disconnecting/connecting live connectors → always disconnect the battery.

- Unseated connector / unsecured fuse → check the security visually and mechanically after connection.

- Unit swap without matching codes → stick to exact part numbers.

- Ignoring the cause of the original fault (moisture, wiring) → eliminate the source of the problem first.

Assembly and Coding – Important

– The unit is used and is “paired” with the original car (VIN/PIN/keys).

– Commissioning options:

1) Cloning data from the old drive (EEPROM/Flash) – after the clone, the drive is plug and play.

2) Virginization and subsequent initialization/telecoding via DiagBox (possibly online) + customization of keys.

– Recommended to be performed by a specialist with PSA service equipment (DiagBox/Lexia/PP2000).

– Always disconnect the battery before disassembly/assembly and follow the manufacturer’s procedure to avoid damaging the unit.Reasons why the part is damaged

- Voltage fluctuations in the on-board network (weak battery, bad charging, inappropriate starting/connection of sources).

- Leaks and moisture in the installation space of the unit or in the connectors.

- Damaged wiring, oxidized pins, transition resistors and subsequent overheating of contacts.

- Incompetent handling (disconnecting connectors under voltage, mechanical stress on the bundle, poor securing of connectors).

- Short circuits in peripherals (e.g. in power branches/actuators) which can overload the unit.