Description

Rear window wiper motor for CITROEN C5 I II station wagons

Part description

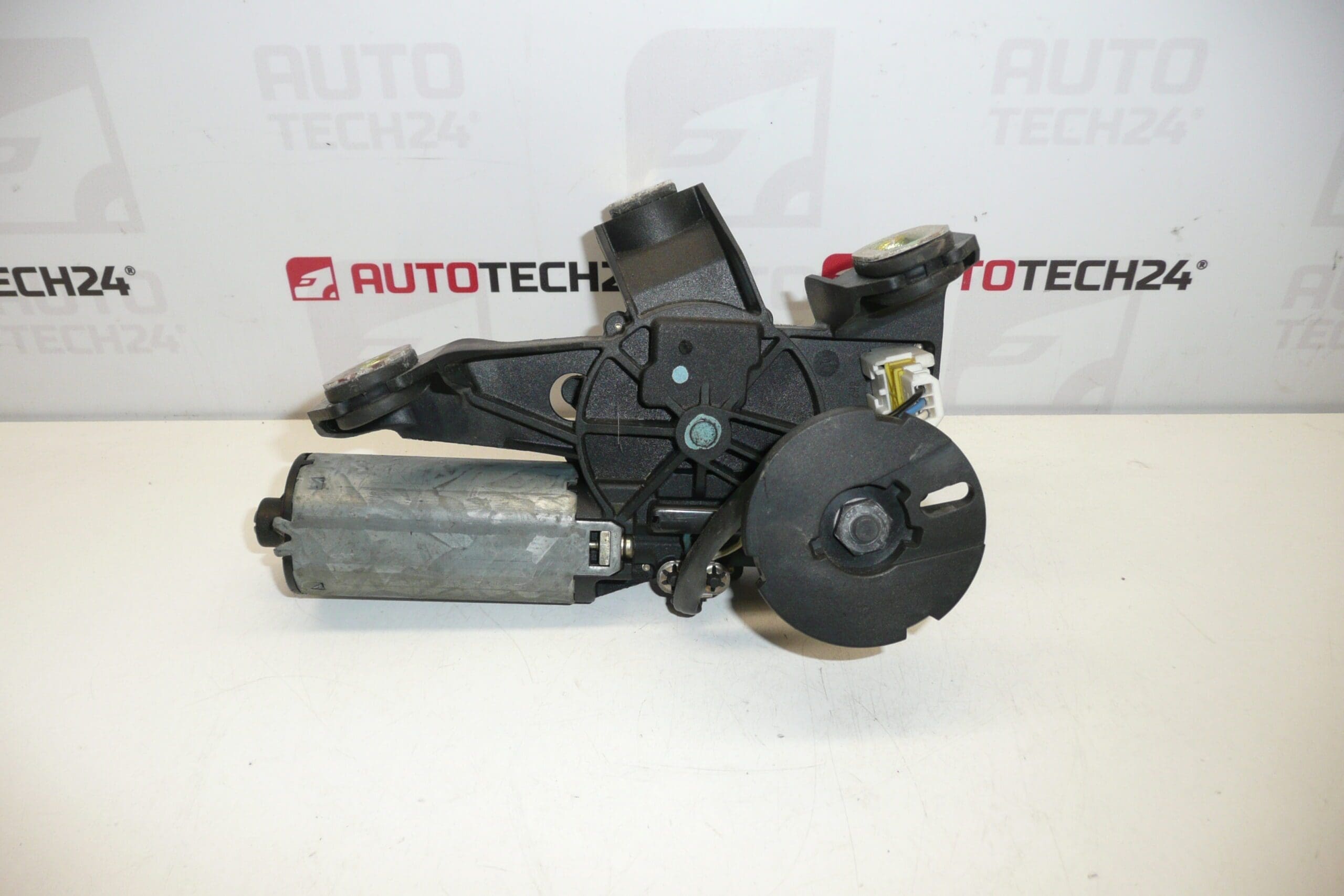

The offered part is a Valeo rear wiper motor intended for the Citroën C5 I/II in the station wagon version. It serves to drive the rear wiper mechanism and ensures smooth operation of the rear window wiper. If you are dealing with a malfunctioning rear wiper, intermittent operation or the motor just “buzzing” without moving the arm, replacing the wiper motor is usually a quick and effective solution.

For correct identification, we recommend following the product numbers listed below.

Technical information

- Manufacturer: Valeo

- Model: Citroën C5 I II station wagon

- Other numbers: 03, 54904512, 6405K1, NFP

Product codes

- Product codes: 9638335780, 6405K1, 54904512, 03

Installation recommendations

Generally/typically for the rear wiper motor, the exact procedure may vary depending on the specific car design and type of mechanism attachment. Below is a practical one-size-fits-all procedure for replacing this type of part.

1) Before assembly (checks of used part)

- Compare the part numbers (eg 9638335780, 6405K1) with the old part and the label/marking on the part.

- Check the connector (shape, number of pins, securing) and overall condition of the cable connection.

- Inspect the motor shaft/outlet and mounting: they must not be cracked, squeezed or significantly corroded.

- If the original fault could have been in the mechanism (stiff tie rod, baked-in bearing), check the free movement of the mechanical parts – the new motor should not be installed in a “stuck” mechanism.

2) Necessary tools and materials (in general)

- Basic set of keys and sockets, ratchet

- Screwdrivers / plastic crowbar for removing upholstery

- Contact cleaner (as needed), cloth

- Protective gloves

3) Step-by-step assembly procedure

- Turn off the ignition and disconnect the battery for safety.

- Provide access to the rear wiper motor (typically removing the inner trim of the fifth door).

- Disconnect the motor electrical connector and check that the pins are not oxidized or loose.

- Loosen the motor/mechanism fasteners (bolts/nuts depending on design).

- Remove the old motor carefully – do not damage the wiring or grommets.

- Clean the mating surfaces and check the condition of the seals/grommets at the passage (if included in the assembly).

- Place the new motor in the correct position and screw the mounting.

- Connect the electrical connector and make sure it clicks/locks properly.

- Before final assembly of the lining, briefly test the function (after connecting the battery): the motor must run smoothly without unusual noises.

- If all is well, disconnect the battery again (as needed), finish installing the trim and seat everything carefully.

- Connect battery, do final rear wiper test.

-

4) Post-assembly checks and functional test verification

- Verify regular operation and return to rest position (wiper parking).

- Check for rubbing, clicking and engine overheating.

- After the first cycles, visually check the fit and connector again.

5) The most common assembly mistakes + how to avoid them

- Part replacement by appearance – always compare product numbers (9638335780 / 6405K1).

- Damage to connector/pins when disconnecting – use proper unlocking procedure and possibly contact cleaner.

- Not tightened or poorly seated mounting – can cause vibrations, noise and erratic operation.

- Stiffened or dirty wiper mechanism (increased resistance → motor overload).

- Moisture ingress into the motor/connector space and subsequent corrosion of the contacts.

- Mechanical stress (backlash, vibrations, damaged attachment, shocks with a frozen wiper).

- Electrical problems in the power supply (oxidation, transition resistances in the connectors).