Description

Complete BEHR digital air conditioning bundle for Peugeot 307 cars up to 2004

Part description

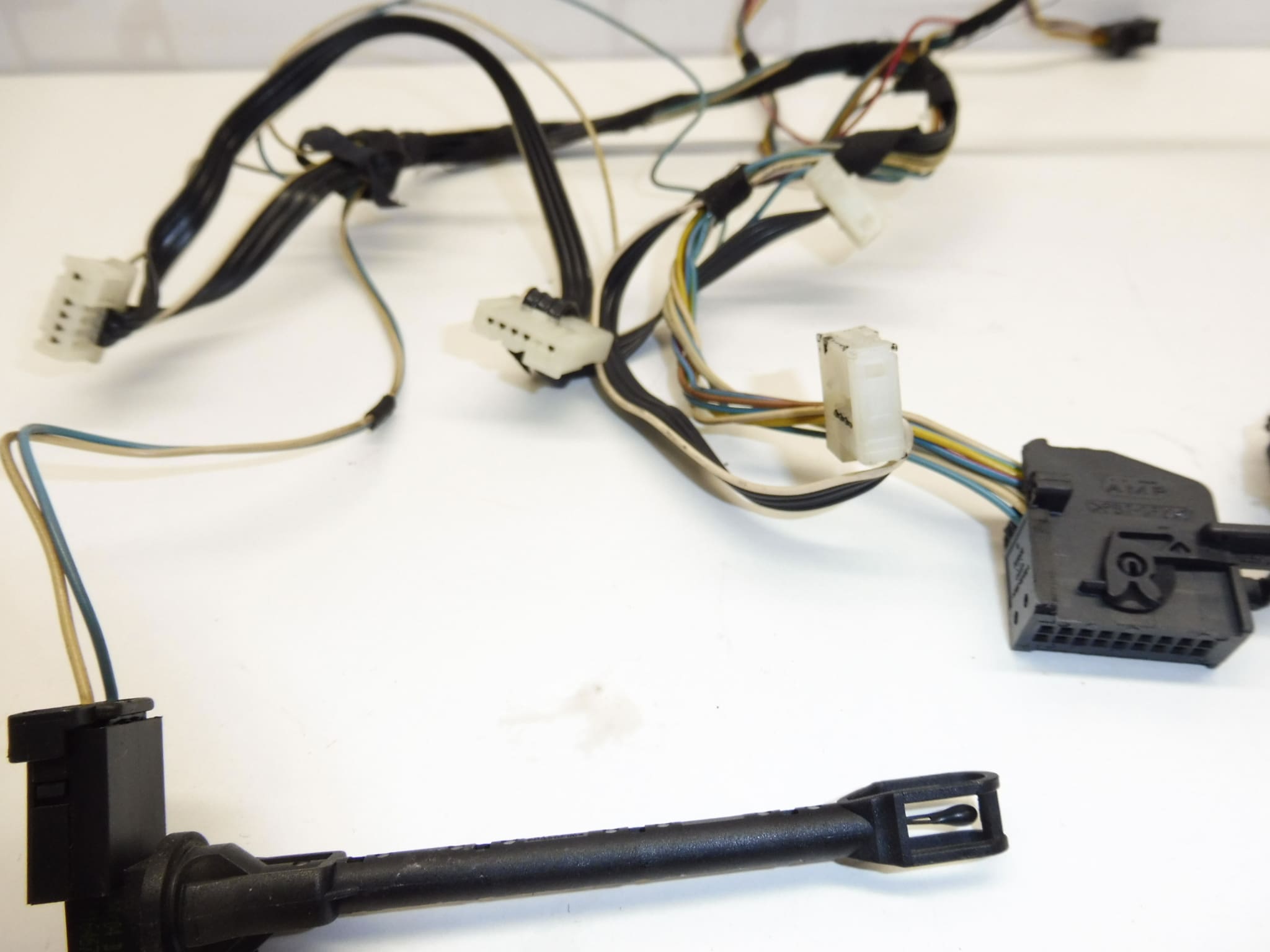

This air conditioning cable harness is intended for the connection of digital air conditioning elements and their interconnection within the vehicle electrical installation. It is a part that is often solved in the event of malfunctions such as intermittent air conditioning function, non-functioning controls or damaged cabling (e.g. after unprofessional disassembly or intervention in the installation).

It is mainly searched for by the BEHR designation and product numbers, which are listed below – when replacing, the key is to compare the markings and design of the harness with the existing part in the car.

Technical information

- Manufacturer: BEHR

- Model: Peugeot 307 up to 2004

- Other numbers: D5384, NFP

Product codes

- Product codes: D5384, 6445ZV

Installation recommendations

Generally/typically for air conditioning wiring harness replacement, the exact wiring of the harness, the location of the connectors and the disassembly procedure depends on the specific car design and equipment. Therefore, always compare the new and the original volume piece by piece.

1) Before assembly

- Visually inspect the entire bundle: insulation damage, cracked/broken wires, traces of overheating, oxidation.

- Check connectors: unsqueezed pins, unbroken locking latches, cleanliness of contacts.

- Compare with the old part: codes D5384 and 6445ZV, number of connectors, their shape and keying, branch lengths and mounting.

2) Necessary tools and materials

- Basic screwdriver and bit set, small ratchets/accessories

- Plastic crowbars for removing upholstery/covers

- Clothing pliers, new cable ties

- Electrical contact cleaner (as needed)

- Insulating tape / textile tape for cabling (as needed)

3) Step-by-step assembly procedure

- Turn off the ignition and disconnect the battery (to avoid short circuits and damage to electrical parts).

- Get access to where the harness runs (remove any necessary covers/trims to avoid snapping the mounts).

- Before disconnecting the connectors, mark the individual branches (e.g. with tape) or take photo documentation.

- Disconnect the connectors of the original harness one at a time – always release the connector locks, do not pull on the cables.

- Release the bundle from the handles and guides (clips, holders, tapes) and remove it without damaging the surrounding installation.

- Place the new bundle next to the original and compare the branch lengths, connectors and branching again.

- Guide the new bundle along the same route as the original to avoid chafing on sharp edges or pinching.

- Snap the bundle into all of the original mounts/holders and secure it so it doesn’t move or stretch.

- Connect the connectors one by one – make sure they fit correctly and secure the fuses.

- Check that there are no loose connectors and that the wiring does not interfere with moving parts or rest on hot parts.

- Reinstall the removed covers/trims.

- Connect the battery and perform a basic function check of the A/C/control system.

-

4) Post-assembly checks and test drive/function verification

- Verify that the climate control responds normally and does not drop out when the wiring is moved.

- Check if there are any dropouts after assembly caused by a poorly snapped connector.

- After a short ride, check again that the harness does not rub anywhere and is properly attached.

5) The most common assembly mistakes + how to avoid them

- Swapping connectors – marking before disassembly and comparing shapes/keying will help.

- Wires torn from the connector – always disconnect the connectors via the fuses, do not pull on the cables.

- Poor bundle routing (abrasion, pinching) – keep the original route and all the grips.

- Unsecured connectors – try to “tighten” the connector back slightly after connecting; must not be released.

Reasons why the part is damaged

- Mechanical damage to the cabling (abrasion on the edges, pinching during the installation of interior parts, pulling on the bundle).

- Aging of the insulation and breakage of wires in stressed areas.

- Oxidation of contacts and increased transition resistance in connectors (moisture, pollution).

- Unprofessional interventions in the electrical installation (additional modifications, connections without proper securing and insulation).

- Loose mounting of the bundle – subsequent vibrations lead to penetration and interruption of the wires.