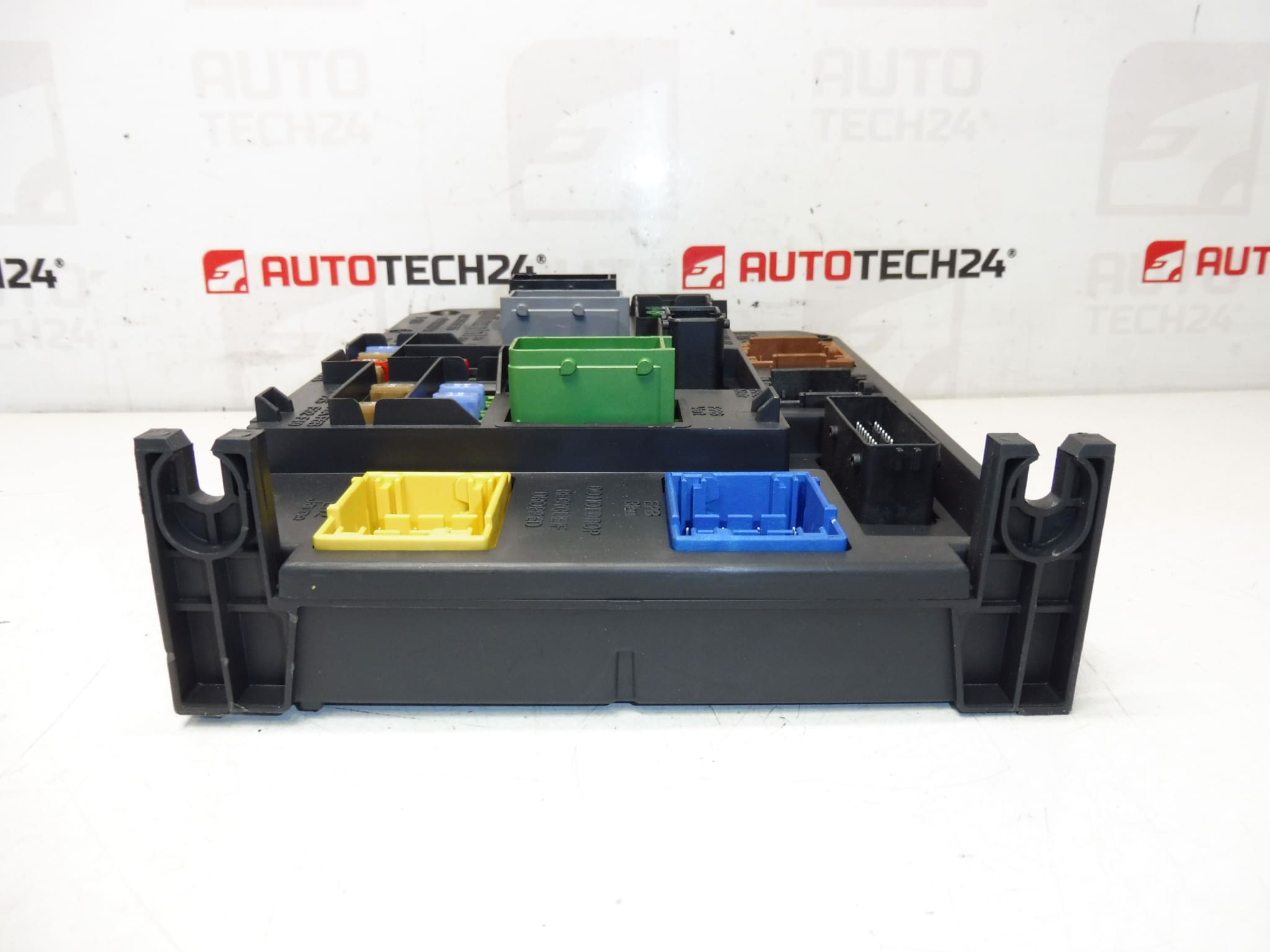

Description

BSI-Q01-00 Continental for Citroën C4 II vehicles. It is from a Citroën C4 II 2011.

Overview

This BSI Q01-00 (Body Systems Interface) unit by Continental is the central body computer for Citroën C4 II vehicles. The module manages and coordinates numerous body functions — including central locking, lighting, wiper control, interior electronics, CAN bus communications and immobiliser interfaces — and is commonly referenced by OEM numbers such as 9665547280, 1616786580 and 6580YP. Suitable for mechanics and experienced DIYers, this unit is a direct replacement part for vehicles using the same BSI-Q01-00 specification.

Technical Information

- Manufacturer: Continental

- Model: Citroën C4 II (2011)

- Product Codes: 9665547280, 1616786580, 1663368180, BSI-Q01-00

- Other Numbers: 6580YP, 6580YQ

What This Part Does

The BSI is the vehicle’s body control computer. It processes inputs from switches and sensors, distributes commands to actuators and relays, and serves as a gateway between subsystems over the CAN bus. When functioning correctly it ensures reliable operation of lighting circuits, central locking, wipers, instrument cluster messages and immobiliser communication.

Symptoms Of A Faulty BSI

Typical signs of a failing BSI include intermittent or permanent loss of central locking, nonfunctional interior or exterior lights, erratic wiper operation, warning lamps on the dash, communication errors on diagnostic tools and, in some cases, immobiliser or starting problems. Faults often appear as multiple unrelated electrical issues rather than a single obvious failure.

Installation Recommendations

Installation should be performed by a qualified technician or an experienced DIYer comfortable with vehicle electronics. Key steps:

- Disconnect the negative battery terminal before starting to avoid short circuits and protect the vehicle electronics.

- Locate the BSI (commonly behind the glovebox or under the dashboard on Citroën C4 II models) and take clear photos of connector positions before removal.

- Carefully release wiring connectors and any retaining clips or screws; avoid pulling on wiring harnesses.

- After physical installation, the unit will frequently require coding or synchronization with the vehicle (immobiliser and keys). Use the manufacturer diagnostic equipment or a compatible tool (e.g., DiagBox/Lexia or equivalent) to program and verify functionality.

- Check battery and charging system health before and after replacement. Voltage irregularities can damage control units.

Why This Part Typically Fails

BSI failures are most often caused by environmental or electrical stress rather than simple wear. Common causes include water ingress or moisture leading to corrosion, voltage spikes or poor battery/alternator performance, past short circuits or intermittent grounding, and damage during previous repairs or modifications. Age-related electronic component degradation and connector corrosion also contribute to failure.

Notes For Buyers

This item is a used BSI unit removed from a 2011 Citroën C4 II. Confirm compatibility by matching the product codes listed above. Because the BSI interacts with immobiliser and key data, expect diagnostic programming or synchronization as part of the installation. For professional results, perform a full post-installation test of lighting, locking, wipers, instrument cluster messages and engine start/immobiliser functions.

High-quality replacement of the BSI restores reliable body-function control and resolves many intermittent electrical faults on Citroën C4 II vehicles. If you are a mechanic or an experienced DIYer, this direct-fit Continental BSI-Q01-00 is a cost-effective solution when the original module shows the symptoms described.